Everything You Need To Know About Chemical Auxiliaries

One of the remarkable characteristics of the human species is that we don’t just stop at discovering new methods and processes, but as time goes by and generations turn, we try to enhance the discovered processes and methods to make them better and more efficient. Since the advantages of woven textiles over animal hides were discovered in the Neolithic age, mankind has been discovering ways to make the textile production easier and textile processing more fruitful to make the end products more valuable and likeable.

Even during antiquity, different organic chemicals were used to enhance the appearance of textiles. For example, oils were used to improve the smoothness of the yarn during spinning and weaving, starch to stiffen the textile and inorganic mordants to fix the colourants. However, it was during the rise of industrialization that chemical auxiliaries for Textiles gained ground.

Everything You Need To Know About Chemical Auxiliaries

Chemical auxiliaries for textiles are essential additives during Textile Processing and are highly significant when it comes to improving their functional and commercial value. Chemical Auxiliaries enable certain stages in Textile Processing to be effectively carried out in order to obtain the desired result. The market for textile chemical auxiliaries boomed when the requirements for the processability of raw materials and the appearance and feel of textiles became more demanding. Over time, highly defined textile processes evolved and so did various chemical auxiliaries that must be used in every stage of the process to obtain the desired result.

To make a woollen product, for example, wool has to be soap-washed and treated with appropriate lubricants prior to spinning, warps had to be sized and finally, the product must be treated with finishing agents to obtain the final commercial product. Thus chemical auxiliaries such as washing agents, lubricating agents, sizing agents and finishes were required to process the material and obtain the desired output from the final product.

A Brief History of Chemical Auxiliaries

The development of modern chemical auxiliaries for textiles dates back to the 1830s when Mercer Runge observed that oils and fats can be made water-soluble by treating them with sulphuric acid. The period from the 1850s to 1950s is marked by various significant historical developments in textile chemical auxiliaries including the invention of the first versions of high-activity wetting agents, synthetic sizing agents, permanent finishes, synthetic softeners and levelling agents. In the 1950s and 1960s, a number of processes for the manufacture of easy-care garments were introduced.

Along with this development, the growth of synthetic fibre production also led to the booming of textile chemical auxiliaries. Now that we know what chemical auxiliaries are and got a gist about their history, the next natural question is if we really need chemical auxiliaries at all? As with any consumables, textiles too, have a commercial angle. The value of textiles, for the most part, is calculated in terms of their final look and feel. Textile chemical auxiliaries play an undisputably significant role when it comes to enhancing the textiles’ look and feel. Starting from the Pretreatment stage until Finishing, there are innumerable chemical auxiliaries available for each stage that add value to the textile at every step of the process.

Types of Chemical Auxiliaries

Textile chemical auxiliaries are classified based on many types. Fundamentally, chemical auxiliaries for textiles are divided into two depending on whether they are permanent or temporary. Permanent chemical auxiliaries are usually applied in the finishing stage in order to retain the auxiliaries’ properties throughout the lifecycle of textiles. Temporary chemical auxiliaries such as soaping agents, levelling agents, desizing agents are used during the textile processing stages and their functionality is limited to the time period during which a processing stage lasts.

Another way of classifying chemical auxiliaries is based on interfacial tension as surface-active, non-surface active and water-insoluble solids. Based on their composition, chemical auxiliaries are also classified as enzymatic, organic and inorganic. Out of the innumerable chemical auxiliaries available, surface-active chemical auxiliaries comprise the majority. They are very dominant that chemical auxiliaries are often considered synonymous to the surface-active ones. Based on their electrolytic property, surface-active chemical auxiliaries are classified as ionic - cationic, anionic, amphoteric and non-ionic.

List of Chemical Auxiliaries and their Functions

The functions of a few commonly used chemical auxiliaries are listed below.

1. Scouring Agents are used for removing natural impurities from the yarn.

2. Bleaching Agents are used for removing the natural colour of the yarn or fibre and usually used before dyeing or printing.

3. Antifoaming Agentsare used for decreasing the foaming effect which can reduce the dye-uptake in the fabrics.

4. Dispersing Agents are used along with Disperse dyes to make them water-soluble.

5. Soaping Agents are used for removing the unfixed dyes from the fabric.

6. Neutralizing Agents are used for neutralizing the pH of the dye bath.

7. Sequestering Agents reduce the hardness of the water.

8. Fixing Agents fixes the dye on the fabric.

9. Levelling Agents are used to enable uniform dye uptake by the fabrics.

10. Bindersare used to lock the pigment particles on the fabric surface.

11. Thickeners are used to impart stickiness and plasticity to the printing paste so that they can be easily applied to the fabric surface.

12. Finishing Agents encompass a wide range of finishes such as softeners, flame retardants, oil repellents etc., to enhance the final look and feel of the textiles.

In addition to the above, there are plenty of other chemical auxiliaries used in Pretreatment, Dyeing, Printing and Finishing. Chemical auxiliaries usually vary in their functional properties based on the industry they are employed in.

The Future of Chemical Auxiliaries

As the market for textile chemical auxiliaries keeps growing, making them more efficient and environmentally friendly has become the need of the hour. At the turn of this decade, the rising water crises and the increase in the cost of utilities for production have led to the need for efficient, intelligent and responsible chemical auxiliaries. In order to ensure that the products and processes are safe for the environment, textile processing and manufacturing units can opt for GOTS and ZDHC certified chemical auxiliaries which cause less harm to the environment.

Where to buy the best Chemical Auxiliaries?

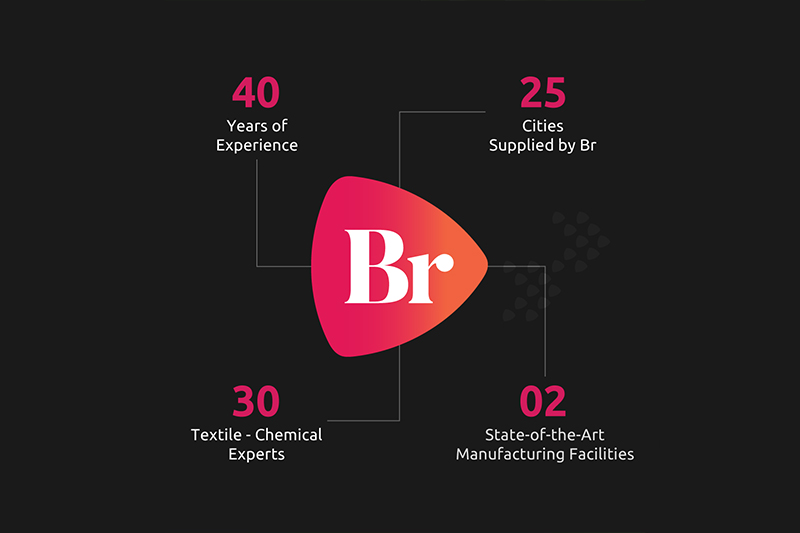

There are a number of vendors who offer GOTS and ZDHC certified products. BR Specialities offers a range of high-performance chemical auxiliaries for Home Textiles, Activewear, Workwear, Automotive Textiles and Garment Industries. With 40 years of experience in the industry, BR aims to provide the highest value to customers through it’s thoughtfully engineered products. To know more about our offerings in detail, contact us.

Your Comments

INDUSTRIES WE SERVE